Hardware-Firmware-Software production and digital solutions

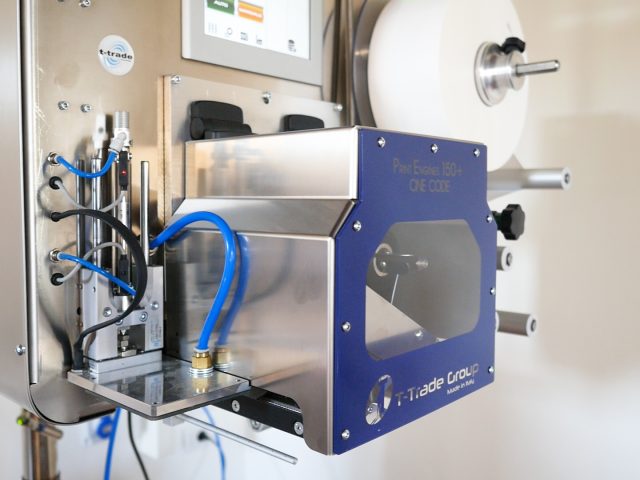

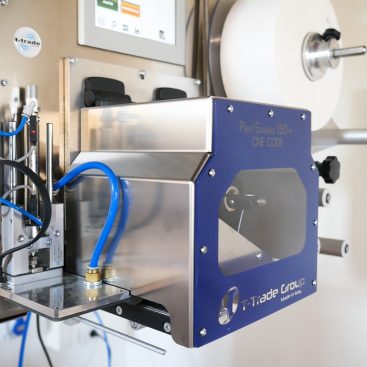

The T-Trade Printing Technologies Division is a unique synthesis in the world, which includes: 18 invention and application patents, Industry 4.0, eco-sustainability, digitization, safety, traceability, circular economy.

Our goal is to reduce the depletion of raw materials. For this we plan, develop and produce environmentally and economically sustainable labeling systems.

T-Trade Print and Print and Apply Systems, Solutions for the tracking and tracing of products and shipments, innovations for labeling that does not require a label, are the maximum expression of: research and development, digitization, eco-sustainability, affordability, all rigorously Made in Italy. The patented and Industry 4.0 solutions are the result of a profitable collaboration with the Polytechnic University of Marche.

Printing Systems with Linerless technology

T-Trade printers and print/apply in line or end of line are linerless technological solutions that have a double advantage:

- are eco-friendly

- are economical

Since they allow 50% or 100% less paper to be used in the labeling process (linerless paper reels have no liner, i.e. waste, which is generally produced with silicone paper; linerless BOPP is polypropylene, always waste-free), drastically reduce the impact that paper manufacturing produces on the environment (felling of trees, water and energy consumption, CO2 emissions). Furthermore, during their activity, thanks to an internal intelligence, they communicate exactly how many trees are saved, how much water is saved, how much less CO2 is emitted into the atmosphere. They also communicate real-time data on machine maintenance needs.

Those who use these systems obtain a considerable reduction in the costs of the labeling process: in fact, the costs of die-cut labels are eliminated, warehouse space is saved as it is possible to avoid the stock of labels of different formats (linerless allows a single reel for multiple formats as the labels are modified on site and on demand); since the liner is missing, the thickness of the reels is lower therefore continuous reels with a diameter of up to 300 mm (900 linear meters) can be used, tripling machine operation and reducing by 2/3 the working time due to label roll change .

The Tape and Print Systems

Another real revolution is to eliminate the label in the shipping package. The T-Trade Tape and Print systems can do this because they print the variable data required for shipping directly on the adhesive tape (or on adhesive paper linerless), which in any case must be used to close the box.

These systems also offer information on predictive maintenance and are able to communicate and provide data on their eco-sustainable activity. They also offer economic advantages as they completely eliminate the end-of-line labeling station, allowing for considerable savings.

The other “printing revolutions”

In its research always aimed at preserving the resources of the Planet and promoting increasingly ethical labeling systems, T-Trade has designed, developed, produced and patented many other printing solutions with different purposes.

From printing on any compostable and biodegradable material – even on a material already existing in nature, like a leaf! – useful for example for more modern and sustainable ticketing, to the printing of data transmitted by scales weighs directly on the handle of the shopper or on the paper bag used in supermarkets. In this case, just to give two examples: no more label on the compostable fruit and vegetable shopper (which remains, thus, totally compostable itself) and no more label on the paper bag used in the fresh counter.

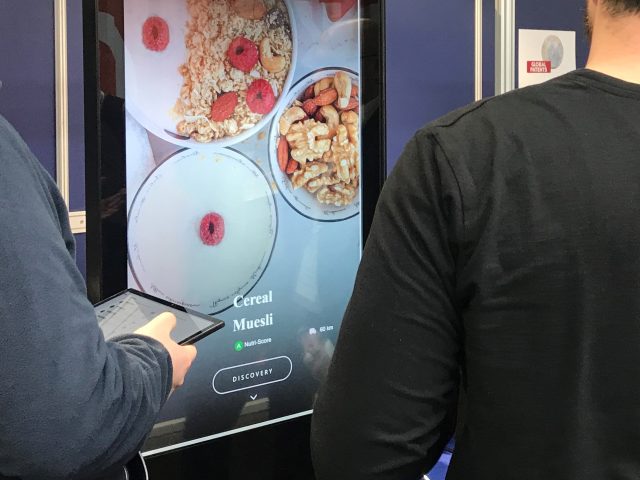

If all this were not enough, T-Trade also produces intelligent printing systems that are able to read the data on any product, create a unique QR independently, print and send all this data to digital platforms and APPs that allow the product to be traced along its entire supply chain (from origin to final use by the consumer), providing in return a series of useful information to the various levels and actors of the supply chain, until the possibility of donating the product, rather than throwing it away, at its expiry or at the end of its usefulness for the final holder.

The research and development of all the solutions described are the core of the activity of the innovative startup TerraMatrix.